|

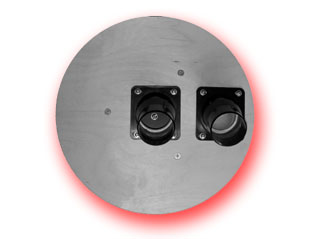

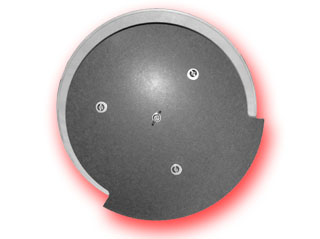

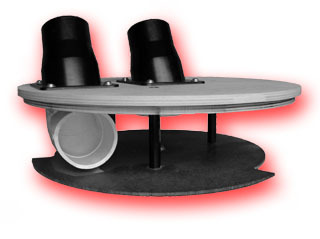

My shop is small, and I use a shop vac for "dust collection." Without starting a debate over what constitutes dust vs. chip collection, I'm just going to say that my tools really were designed for extraction with a shop vac instead of a dust collector. I have a tiny Inca bandsaw w/ a 1.25" port, a table saw w/ a 2.5" port, and my router table's down-draft box works better with the larger static lift of the shop vac than it would with the higher air volume of a "true" dust collector. So for the time being, I decided to stick w/ models of cyclone lids intended for use with shop vacs. I started by rearranging my shop and installing some 2.5" flexible hose as a dust collection network. I used some Y's and blast gates and discovered that, because my shop was quite small and the flexible pipe runs very short (a total length of 9' from one end to the other), the flexible hose worked great. Next, I tried three different commercially-available cyclone lids. I was disappointed with the amount of debris that still made it back to my shop vac. Big chips, not just fines! Worse yet, even when I was no longer cutting (or planing or jointing), running the shop vac resulted in a constant scrubbing (an exodus of material from the "cyclone" bin back to the shop vac. This just wouldn't do! So I spent approx. the last two years developing and perfecting my own design. I've gone through nearly fifty designs/variations. Now I find myself with a cyclone lid that approaches true cyclones in separation efficiency, and which isn't susceptible to the scrubbing that all the commercial offerings I tested suffered from. The trick of my design is the baffle I've added. This specially shaped baffle creates a separate cyclonic chamber at the top of the unit. The baffle reduces the amount of turbulence that hits the already settled debris in the bottom of the bin. Furthermore, the baffle guarantees that any debris that HAS been reactivated by turbulence will have to re-enter the cyclonic motion before getting a chance to exit the output tube (and debris that was heavy enough to settle once will likely settle again). Finally, the baffle allows you to fill the unit to within 3" of the top of the can (the bottom of the baffle) without any penalty in terms of separation or scrubbing. In fact, I've actually slightly overfilled my unit on a number of occasions with little consequence. All three commercial units I tested had performances that were inversely proportional to volume utilized (getting progressively worse past 1/4 full). I've uploaded a brief demonstration movie of my cyclone lid in action (yes, YES, I need to edit it down--that will get done soon). Furthermore, I've included some pictures here that show the top, bottom, and side views of the cyclone. I'm working at documenting the design further and will get that stuff posted as quickly as possible for those that may be interesting in building their own. If there is enough interest in this design I will add some time-lapse video that demonstrates the superior resistance to scrubbing and backup my capacity claims. BTW, while my demo model is only intended for use with a shop vac, this design does scale well. I have made units for use with dust collectors and am currently constructing a model with twin 4" inputs and a single 6" output that will be quite awesome. I have also modded single-stage dust collectors with my baffle (this allows units with cartridge filters on top to stay cleaner, longer). I will post some pictures and details as soon as I have the time (EOY is always especially busy for me). I have created a discussion forum where I will happily answer questions and where (hopefully) any answers can benefit others, as well.

Links

--Phil This page has been viewed 773229 times. |

|||||

|

This site is sponsored by Milwaukee's computer repair specialists. |

The

Thien Cyclone Separator Lid

The

Thien Cyclone Separator Lid