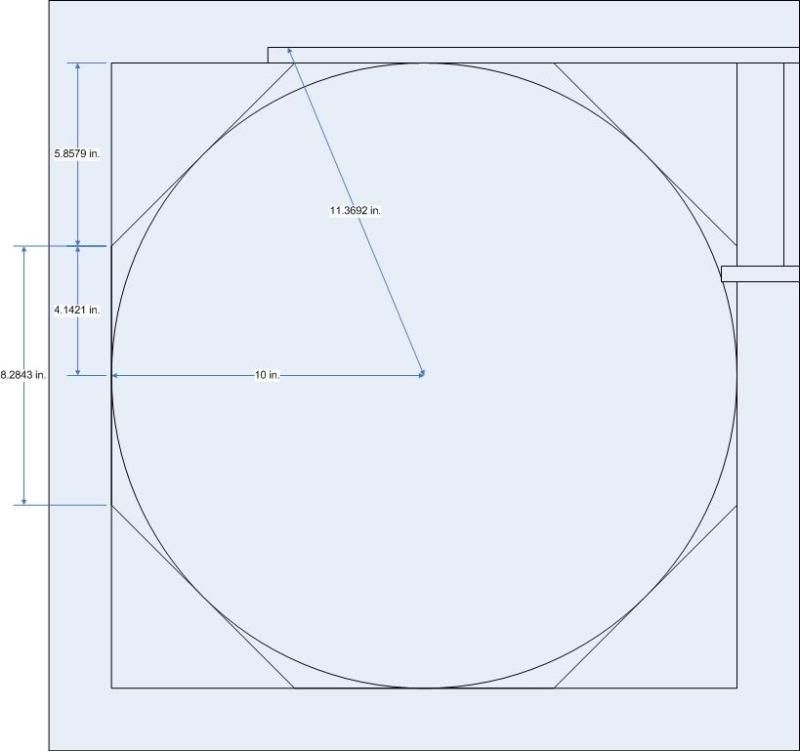

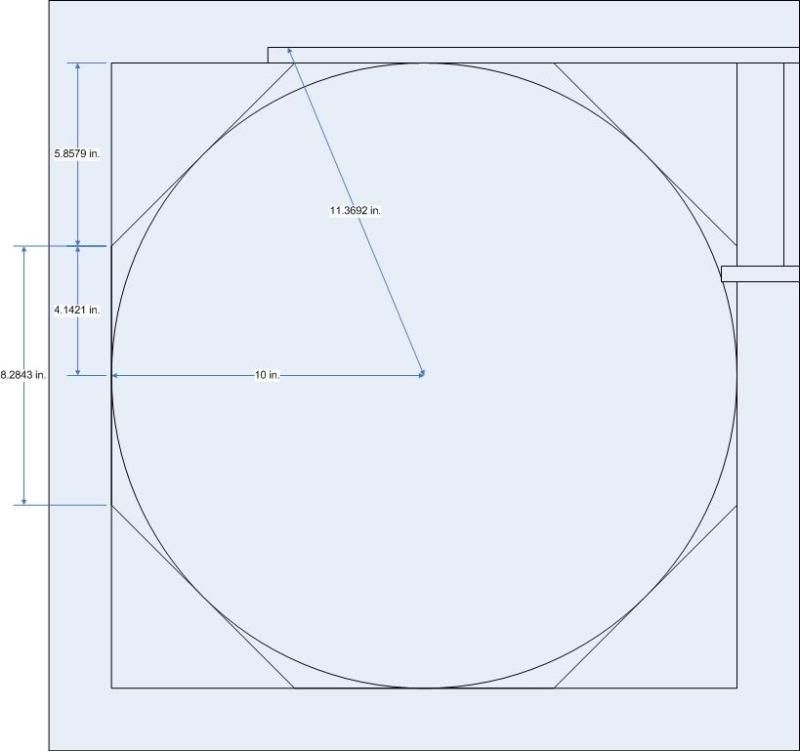

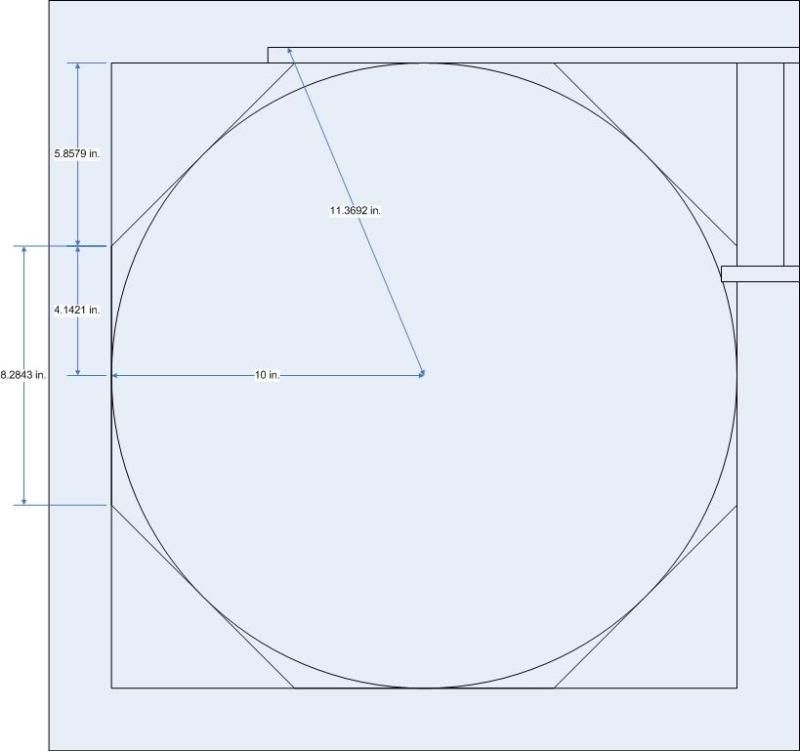

I had somebody ask me about design on this. So, I am posting my basic incomplete rendering I did with visio while I was thinking throught the design.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu