|

My

drill

press column-mounted fence My

drill

press column-mounted fence

Copyright (c) 2012, all

rights reserved.

My normal drill press table

and fence have served me well, but there was one type of operation

where it fell short: Drilling holes in the EDGES of

workpieces. Especially when the workpieces were larger

rectangles and I needed to drill holes in all four edges. This

would require moving the table, which meant the fence lost registration.

This need arose again when

I was working on a dust shoe for a CNC router (more on that some day

in the future). I had very nicely machined a piece of

polycarbonate (on the CNC router itself) and was now needing to drill

1/8" diameter holes around the perimeter of this 4" x

7" (or so) piece of plastic.

Using the shorter fence on

my drill press table was futile. The fence itself is only about

2" high, so it simply didn't provide enough support near the top

of the workpiece. The result was holes that weren't perfectly

centered in the edges of my little piece of plastic.

Now, if you know anything

about me, you know that just wouldn't do. Because I'm

certifiably insane, I see a line of holes that aren't in perfectly

alignment as abject failure. So it was time for me to revisit

my need for a tall fence, and something that didn't register off the table.

I knew I wanted something

that registered off the column, that would solve both problems I was

having. With a fence registered off the column, the table could

be moved up/down/sideways and neither the fence nor the stop block ON

the fence would move. Also the fence could be placed

immediately below the bit, so my workpiece would be perfectly

supported and my holes would all be in a perfect line.

So I started googling

things like "drill press column fence" and was getting

nowhere. I knew I had seen one design, an old Skil

"HD" (stood for "Heavy Duty" and the stuff was

actually pretty good) had a fence that was an adjustable bar on a

collar that attached to the column. Primitive but...

Nothing else much turned

up. So I decided that once again, I'd need to come up with

something on my own. The pics here are what I've philgineered.

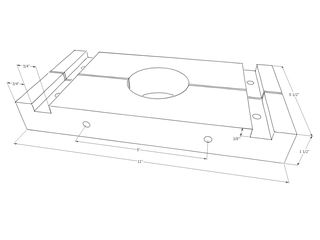

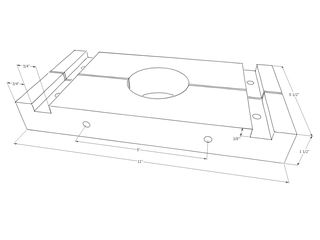

Basically, a nearly

1-1/2" thick piece of Baltic birch plywood (technically two

pieces that are glued-up) is made into an 11" wide split

collar. There are two 5/16-18 carriage screws and knobs that

squeeze the collar around the column. Finally, there are two

dadoes, each 3/4" wide by 3/8" deep in which some Rockler

t-track slides. T-bolts (4) in those dadoes with accompanying

knobs on the bottom snug the t-track up.

The other ends of the

t-track are connected to a small block of wood that is really the

subfence. This block of wood also has some 3/4" wide by

3/8" deep dadoes to capture the ends of the t-track. And

the block has some perpendicular holes (two of them) through which

t-bolts extend. With knobs, these t-bolts snug the actual fence

against which my workpiece rests.

That is a lot of words to

describe what a few pictures will probably do better, so there are

plenty of pictures and an incomplete (I'm working on it, my SketchUp

skills are very slowly improving).

How to make your own...

I always look at pictures

and plans and wonder where exactly to start. Well, I'm going to

give you the exact steps I used to make this one, as best as I can recall.

|

• |

|

Glue up two pieces of

3/4" Baltic birch plywood large enough to net a single piece

11" x 5-1/2" x about 1-1/2" thick. I used the BB

plywood sold as 3/4" thick. It isn't, quite, but whatever

you net from two layers 3/4"-ish thick will be fine. |

|

• |

|

Cut the glued-up piece to

final dimensions (11" long, 5-1/2" wide). |

|

• |

|

You're going to need the

subfence to match the 11" width, so now would be a good time to

also cut a piece of BB plywood that is 11" long by 1-1/2"

wide. Try to use a single stop-block setting while cutting both

the larger block and this sub-fence to the 11" long dimension,

it will save some time in the next steps if they are exactly the same length. |

|

• |

|

Mark the center of the

larger block that will become the collar. You could use a

longer steel rule and draw diagonals, but I typically use a

combination square and make four marks. First, I set the

combination square to half the 11" dimension (so 5-1/2")

and then use it to make a mark from both ends. Now I change the

combination square to half the 5-1/2" dimension and again make

two marks now from both of the long edges. In the middle of

your workpiece you will now have a sort of "#" and you

should be able to visually split the differences very accurately. |

|

• |

|

Measure the diameter of

your drill press column. I used a digital calipers (just a

cheapie I purchased at Harbor Freight, the one that eats batteries

like they grow on trees). I took several readings in a few

different spots along the length of the column, and came up with

2.885". My drill press is a Ridgid floor-standing model, I

imagine column diameters will vary from manufacturer and model to

model, so make sure to measure YOUR drill press column. |

|

• |

|

I now divided my column

diameter in half (1.4425) and adjust my digital calipers to

1.442". I then took a drafting compass and adjusted it

using the calipers. Now draw a circle on your plywood. |

|

• |

|

Now I moved to my router

table to create the dadoes for the t-track. I used a 3/4"

router bit and made a few passes to get to the 3/8" depth I

needed. I used a scrap piece of wood behind my workpiece to

prevent the bit from blowing-out when it exited. |

|

• |

|

Now is the time you also

want to route those dadoes in the sub-fence. If you do it now,

the dadoes between the collar and the subfence will align nicely when

it comes time to assemble the thing with the t-track. |

|

• |

|

Now mark your workpiece for

the carriage screws that will soon squeeze the collar to the

column. In my case these carriage screws are 5" apart, or

2-1/2" in each direction from the centerline. Mark your

lines on the top of your workpiece. |

|

• |

|

Now we get to cut the

collar in half. Align the fence of your table saw so the blade

will as nearly as possible tip the collar into two equal halves. |

|

• |

|

Use a bandsaw or scroll saw

or jigsaw to cut the column hole from the two halves of your

collar. I used my little Skil bench bandsaw with a 1/4"

6-TPI blade. Stay inside the line. |

|

• |

|

To fine-tune the cut, I

alternated between test-fitting the collar halves to the column, and

sanding them on my oscillating belt sander. A drum sander would

also work great for this. Just take your time, sand to the line

slowly, test your fit. I probably test-fit ten times for each

half of the collar, and stopped once the collar halves nicely fit the

column with no gaps. |

|

• |

|

Now drill the holes for

your carriage bolts. I used a saddle square to transfer the

lines I had made on the top of the collar back in step #9 to the

INSIDE of the two collar haves (the sides that will be TOWARDS the

column). And then I found the center of the edge using my

combination square set at half the thickness of the piece, and making

two marks. The difference between the two marks is the

center. I drilled 5/16" holes through each half of the collar. |

|

• |

|

If your drill press has a

rack for raising/lowering the table, you need to accommodate it by

notching the block. I did this on my table saw, nibbling enough

material away from both halves of the collar so the rack wouldn't interfere. |

|

• |

|

Now we can do our first

test tightening. Install the two carriage bolts through the

holes (I seated the heads with a hammer) and assembled the collar

around the column, and used a couple of knobs to snug everything

up. I found I get the best results with one smaller knob and

one larger ratcheting knob. I snug the little knob, and then

crank the ratcheting knob a bit. Once snug try moving the

collar by grabbing it with both hands and twisting it. It

shouldn't budge. |

|

• |

|

Now take it all apart again

and drill your 5/16" holes for the t-bolts. There are four

holes (two in each collar half) and two more in the subfence.

Just center these both length and width-wise in the dadoes. A

good trick for finding marking the center of the dado is to use a

3/8" gauge block and draw two lines and divide those by eye. |

|

• |

|

You will need to drill two

holes into the edge of the subfence for the t-bolts that hold the

actual fence. I can't remember where I placed these, I

will update this page if anyone actually tries building one of these. |

|

• |

|

Make a fence. I make

these from 1" thick wood and I route a t-slot into each

side. The one I'm using now is 1" plywood (actually a

piece of 3/4" and 1/4" scrap glued together). The

t-slot on back allows for mounting the fence to the subfence.

The t-slot on front allows me to add a stop-block. To route a

t-slot, I use a 3/8" straight bit to remove most of the

material, and then a Rockler or Whiteside t-slot bit to finish it

off. A router table is invaluable for this. |

|

• |

|

Now reassemble once

again. You need a couple of 1' long pieces of t-track, some

t-bolts (four to hold the t-track in the dadoes on the collar, two

sets to hold the t-track to the subfence, and two to hold the fence

to the subfence. |

Random notes...

|

• |

|

The t-bolts I used in the

collar didn't extend much below the bottom, I was concerned the knobs

wouldn't get much purchase on them. I ended-up adding a 1"

counterbore (you can use a Forstner bit, I used a piloted

counterbore). I went 1/4" deep.\ |

|

• |

|

The 5/16" holes can be

a little tight for 5/16-18 t-bolts and carriage bolts. My

5/16" drill bit may be a few thousandths undersized, too.

So when I was all done, I reamed-out all my 5/16" holes to

21/64" (this is 1/64" larger than 5/16"). |

|

• |

|

I didn't write-up anything

on making a stop-block, but I'll picture mine here soon.

I use this same stop block for both my drill press and table saw

sled fences. It has a ridge which rides in the t-slot so the

block doesn't twist, and a t-bolt and knob snug it up. |

|

• |

|

You may notice I used some

wingnuts and some knobs on my jig. I didn't do this for any

other reason than I was out of knobs and the prices on those things

is about $1.50 each. A recent PayPal contribution was used for

the t-track, and there wasn't enough left for knobs, so wingnuts it was. |

If you spot any errors or

there is any confusion, please let me know so I can update this

page. I plan on updating it to get rid of the red. This

has been sitting on my hard drive, unpublished, for a couple of

months now. Sometimes the best way for me to get in gear is to

just get in gear, so I'll fix the missing parts soon. Here is a <link>

(soon) to a file with my SketchUp file for the collar.

I haven't drawn the subfence and there is no way my skills are

currently up to adding carriage bolts or t-nuts or t-track,

sorry. I think there is plenty there for the builder, though.

--Phil

phil@cgallery.com

This page has been viewed 12646 times. |

My

drill

press column-mounted fence

My

drill

press column-mounted fence