|

Fine-tuning

your Ryobi BT3000/BT3100/BT3K

table saw

When properly aligned, the

BT3K cuts as precisely as the finest cabinet saw. The saw's

manual does a very good job of laying out alignment procedures that

get it "close enough." Considering that the writers

of the manual had to assume the only calibration tool at the disposal

of the reader was a square, I think their work is quite an achievement.

Of course, "close

enough" isn't good enough, and we want our saws to be

perfect. If you've flipped through woodworking catalogs at all,

you've no doubt noticed tools for aligning table saws. These

are typically aluminum bars that ride in the miter slot and which

hold a dial indicator perpendicular to the slot. Here

is a link to a typical design. They allow users of

contractor saws to align the blade to the table with great

precision. But wait, the BT3K saws don't have miter slots.

And you can't adjust the relationship of the blade to the table,

either. The BT3K is unique, and requires a unique approach.

That is what I offer

here. With a 3" x 10" block of 3/4" plywood, a

bolt & cross-dowel, and an inexpensive indicator (digital or

dial), you can align your BT3K to perfection.

|

|

This is my BT3K

alignment block.

Made from a 3/4" piece

of BB plywood. I used a cross-dowel and two holes drilled

1/2" from the edge. This allows me to arrange my indicator

in the three different configurations I use. The small piece of

1/4" BB at the bottom acts as a fence when aligning the SMT base.

No

precision machining is necessary, the only prerequisite is that the

indicator is securely held. No

precision machining is necessary, the only prerequisite is that the

indicator is securely held.

|

|

Procedure

#1, Check the arbor/blade

runout |

|

|

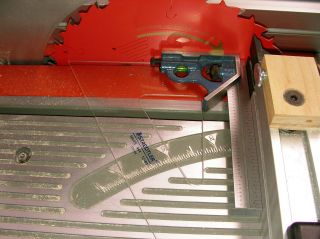

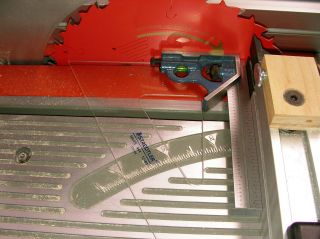

Assemble the alignment jig

in the fashion shown in the photo. The small block of wood

(a.k.a., "the fence") is UP. Set the saw's fence

5-1/2" from the blade and insert the jig. Zero the

indicator. Carefully rotate the blade while observing the

indicator for the range of values.

My

combined (arbor + blade) runout is .004" (four-thousandths of

an inch). Assuming the blade is perfectly flat (they aren't),

that translates into .0005" of arbor runout [that is .004"

/ 8" (the radius point on the blade where you measure times two)]. My

combined (arbor + blade) runout is .004" (four-thousandths of

an inch). Assuming the blade is perfectly flat (they aren't),

that translates into .0005" of arbor runout [that is .004"

/ 8" (the radius point on the blade where you measure times two)].

If

your total measured runout is more than .005", I suggest

removing the blade and cleaning the arbor nut, washers, spacers, and

flange. Clean them with Formula 409. Reassemble and try

again. If you are still measuring significant runout, try a

different blade. If

your total measured runout is more than .005", I suggest

removing the blade and cleaning the arbor nut, washers, spacers, and

flange. Clean them with Formula 409. Reassemble and try

again. If you are still measuring significant runout, try a

different blade.

I

experienced excessive runout (I could see the blade wobble while it

was spinning down) and discovered that my spacers weren't flat.

Replacement spacers from Ryobi fixed it right up. I

experienced excessive runout (I could see the blade wobble while it

was spinning down) and discovered that my spacers weren't flat.

Replacement spacers from Ryobi fixed it right up. |

|

Procedure #2,

Align base of SMT to the blade |

|

|

Your SMT base need to be

perfectly parallel to the blade. Follow these steps to check

its alignment: (1) Configure your jig as in the photo to the

left. The jig's "fence" is DOWN. (2) Raise the

blade as high as it will go, then back it off about .1".

(2) Mark a tooth with an "X" and rotate the blade so this

tooth is towards the front of the saw. (3) Push the indicator

point against the "X" until the jig's fence is flat against

the SMT base. (4) Zero the indicator. (5) Rotate the

blade so the tooth you marked with an "X" is at the rear of

the saw. (5) Move the jig to the rear of the blade and push the

indicator point against the "X." Your indicator

should read zero (0), showing no difference in measurement from front

to back. If not, try again a few times until you are

comfortable with the procedure and to make certain you get repeatable results.

|

|

|

Use the instructions in the

manual (bottom of p. 33), "MAKING ADJUSTMENTS TO SLIDING MITER

TABLE ASSEMBLY/TO ADJUST THE MITER BASE" to make any necessary

adjustments. Once you have made the necessary changes repeat

this section to verify your base is parallel to the blade. |

|

|

Procedure #3,

Align

the miter fence to the blade |

|

|

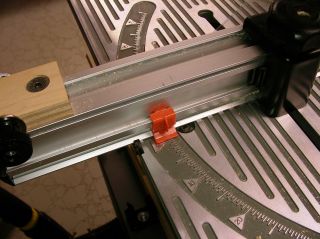

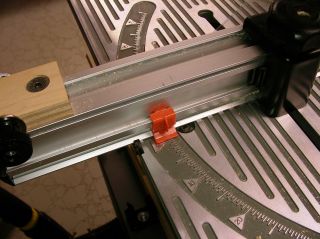

Install the miter fence on

the sliding miter table and set it to 90-degrees (make certain you

use the orange indicator shown in the photo at left). The

graduations are rather thick, so I place the orange indicator to the

top of the graduation. You can use the top, middle, or bottom,

as long as you're consistent.

Now

place your square against the blade and the fence and check your alignment. Now

place your square against the blade and the fence and check your alignment.

|

Use the instructions in the

manual (top of p. 34), "MAKING ADJUSTMENTS TO SLIDING MITER

TABLE ASSEMBLY/TO ADJUST THE MITER FENCE" to make any necessary

adjustments. Once you have made the necessary changes repeat

the steps above to verify your fence is square to the blade. |

|

|

Procedure #4,

Verify alignment

of SMT to blade |

|

|

In procedure #2 above we

made certain the SMT's base was parallel to the blade. Having

done that, the sliding miter table should automatically slide

parallel to the blade. But we may as was well check.

[Trust, but verify.]

Use

the following steps: (1) Configure your jig as in the photo to

the left. The jig's "fence" is UP. (2) Raise

the blade as high as it will go, then back it off about

.1". (2) Mark a tooth with an "X" and rotate the

blade so this tooth is towards the front of the saw. (3) Push

the indicator point against the "X." (4) Zero the

indicator. (5) Rotate the blade so the tooth you marked with an

"X" is at the rear of the saw. (5) While holding the

jig against the fence, carefully slide the table towards the back of

the blade until your indicator point rests on the "X"

again. Your indicator should read zero (0), showing no

difference in measurement from front to back. If not, go back

to "Procedure #2, Align base of SMT to the blade" and check

your work. Use

the following steps: (1) Configure your jig as in the photo to

the left. The jig's "fence" is UP. (2) Raise

the blade as high as it will go, then back it off about

.1". (2) Mark a tooth with an "X" and rotate the

blade so this tooth is towards the front of the saw. (3) Push

the indicator point against the "X." (4) Zero the

indicator. (5) Rotate the blade so the tooth you marked with an

"X" is at the rear of the saw. (5) While holding the

jig against the fence, carefully slide the table towards the back of

the blade until your indicator point rests on the "X"

again. Your indicator should read zero (0), showing no

difference in measurement from front to back. If not, go back

to "Procedure #2, Align base of SMT to the blade" and check

your work. |

|

Procedure #5,

Align the rip

fence to the blade |

|

|

We're almost done! We

just need to align the rip fence to the blade. The fence should

either be perfectly parallel to the blade, or toed-out (away from the

blade at the back) by a couple thousandths of an inch.

Toeing-out the fence is less important if you use a splitter. I

shoot for parallel.

Here

is the procedure: (1) Assemble the jig as shown in the

photo. The jig's fence is UP. (2) Raise the blade as high

as it will go, than back off by about .1". (3) Mark a

tooth with an "X" and rotate the blade so the tooth is

towards the front of the saw. (4) Lock the fence approx.

5-1/2" inches from the blade. This allows the jig to slide

between the blade and the fence, so the indicator point is always in

contact with the blade and the right edge of the jig is always in

contact with the fence. (5) With the edge of the jig against

the fence and the indicator point against the "X," zero the

indicator. (6) Rotate the blade so the marked tooth is towards

the rear of the saw. (6) Slide the jig to the rear of the blade

and place the indicator tip on the "X." Take a

reading on the indicator. It should be zero (0). Here

is the procedure: (1) Assemble the jig as shown in the

photo. The jig's fence is UP. (2) Raise the blade as high

as it will go, than back off by about .1". (3) Mark a

tooth with an "X" and rotate the blade so the tooth is

towards the front of the saw. (4) Lock the fence approx.

5-1/2" inches from the blade. This allows the jig to slide

between the blade and the fence, so the indicator point is always in

contact with the blade and the right edge of the jig is always in

contact with the fence. (5) With the edge of the jig against

the fence and the indicator point against the "X," zero the

indicator. (6) Rotate the blade so the marked tooth is towards

the rear of the saw. (6) Slide the jig to the rear of the blade

and place the indicator tip on the "X." Take a

reading on the indicator. It should be zero (0).

|

To make adjustments, follow

the instructions on top of p. 29 of the manual ("TO CHECK THE

ALIGNMENT OF THE RIP FENCE TO THE BLADE"). Once you've

made any changes, repeat the steps in this section to verify the

fence is now properly aligned. |

|

|

Procedure #6

(Optional),

Check the blade for 90-degrees |

|

|

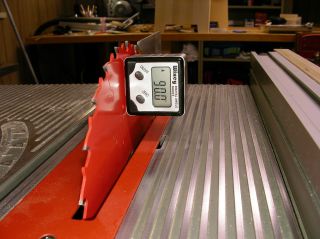

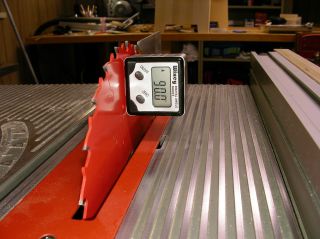

Extra Credit:

The five procedures above don't really require that the blade be set

to 90-degrees to work correctly. However, most of my cutting is

done at 90, so I like to make certain I have my blade set

correctly. I use my Wixey Digital Angle Gauge to do this.

Set the gauge on the table and zero it. Then attach it to the

blade and adjust the blade until you read 90-degrees. Spot-on! |

Some final thoughts...

(1) Depending on where you

keep your SMT on the rails, you may need to adjust the size/shape of

your jig. My SMT is to the immediate left of my table, so that

is how I arrived at the size/layout of my block.

(2) I have found that

raising the blade all the way to the top (where you begin to feel

resistance) causes up to .006" of distortion from the front to

the back of the blade. All you have to do to correct this is

lower the blade about .1"

(3) It is necessary for the

SMT table to slide on its base with no side to side play. See

p. 33 of the manual to eliminate play in the table. If you have

any difficulty moving the table after this, wax the edges of the SMT

base (use some wax paper, or some Johnson's paste wax, or my

favorite, Waxilit). If it is still difficult to move, you

tightened it too much. :-)

(4) When taking readings

using the jig, it is possible to distort the readings by pushing down

or sideways on the jig with any force. Apply the minimum

pressure necessary to get an reliable reading.

--Phil

phil@cgallery.com

This page has been viewed 47390 times. |